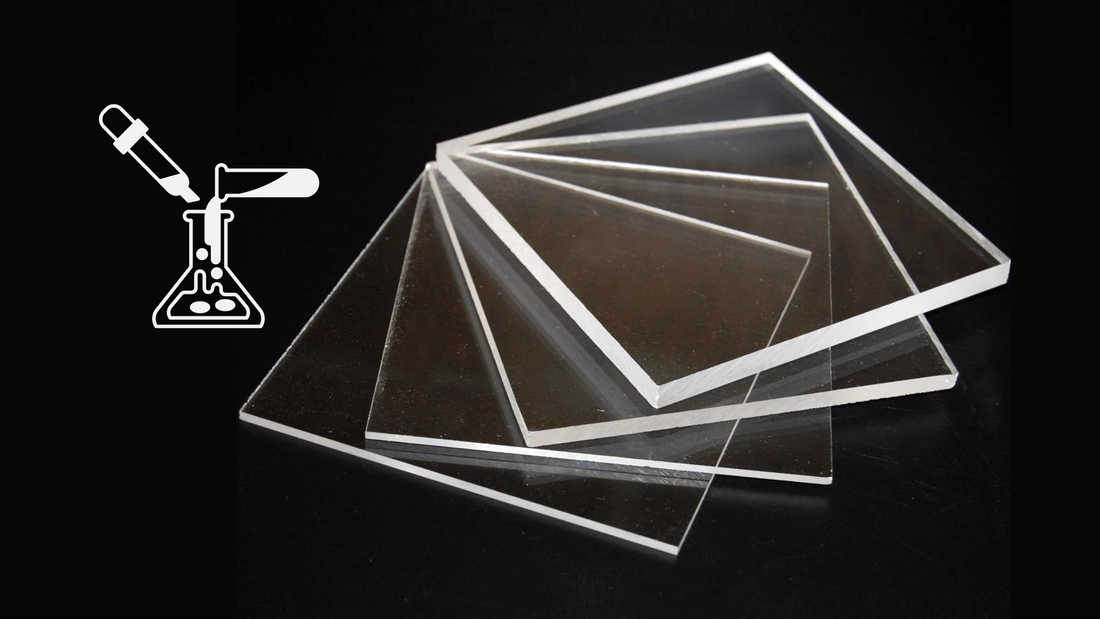

LASER CUTTING AND ENGRAVING ON PLEXIGLASS

Plexiglas®, Acrylic, PMMA: Understand everything for successful laser cutting

Plexiglas®, acrylic and PMMA are terms often used interchangeably to refer to a transparent and durable thermoplastic. But did you know that there are nuances between these names and that the choice of material can impact laser cutting?

In this article, we will shed light on these terms and guide you in selecting the ideal Plexiglas for your laser cutting projects.

Plexiglas®: An iconic brand

The term "Plexiglas®" is a registered trademark of Röhm GmbH for its own PMMA. It is therefore a specific type of PMMA, known for its high quality and wide range of colors and thicknesses.

Acrylic: A generic term

Acrylic is a generic term that encompasses all types of polymethyl methacrylate, including Plexiglas®. It is often used to refer to PMMA more generally, without reference to a particular brand.

PMMA: The scientific name

PMMA is short for polymethyl methacrylate, which is the chemical composition of the material. It is the scientific term used to refer to this type of plastic.

Differences between PMMA types

While all types of PMMA share common properties, some distinctions exist:

- Cast PMMA: Produced by casting in molds, this PMMA offers excellent optical quality and a smooth surface, ideal for laser cutting and engraving.

- Extruded PMMA: Less expensive than cast PMMA, this PMMA is produced by extrusion and has a less smooth surface. It is still suitable for laser cutting, but may require subsequent polishing.

- Recycled PMMA: Made from PMMA waste, this type of material is environmentally friendly but may have variations in color and properties. Its use with a laser cutting machine is possible, but prior testing is recommended.

Choosing the right PMMA for laser cutting

The choice of PMMA for laser cutting depends on your specific needs:

For optimum quality and an impeccable finish, particularly for laser engraving: Choose cast PMMA.

For a tighter budget: Extruded PMMA will be suitable for laser cutting but not for engraving.

For an eco-responsible approach: Recycled PMMA can be an option, but it is important to check its characteristics with the supplier.

Tips for successful laser cutting:

Choose the right PMMA thickness. The thickness of the PMMA will affect the power and speed of the cutting or engraving. Check your laser machine manual for specific recommendations.

- Power. The power of the laser determines the depth of the cut or engraving. It often takes much more power to cut PMMA than plywood.

- Speed. The speed of the laser affects the quality of the cut or engraving. Too high a speed can result in rough edges or blurry engravings. Start with a slow speed and gradually increase it if necessary.

- Focus. The laser focus must be properly adjusted to achieve a clean cut or engraving. Consult your laser machine manual for instructions on how to adjust the focus.

- Cutting PMMA is not recommended on machines without a protective cover and without air-assist.

- Use a fume extraction system. Cutting and engraving PMMA can produce harmful fumes. Make sure you have an effective fume extraction system to remove these fumes from your work area.

- Test your settings on a piece of scrap PMMA. Before cutting or engraving your final project, this will ensure you are getting the results you want.

To go further: article “how to maintain your CO2 laser”

By following these tips, you can achieve optimal results for laser cutting and engraving on PMMA.

PMMA is a versatile material that can be used to create a wide variety of projects, from signage to jewelry to decorations. With a little practice, you can create beautiful and unique PMMA objects with your laser machine.